Sensor

Auto Balancing

Auto Balancing Products

- EXTERNAL BALANCERS

- INTERNAL BALANCERS

- HYDROKOMPENSER

- SB-55xx SERIES

- SB-1000

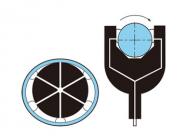

Auto balancing solution is elegantly simple: a computer control panel, a vibration sensor, spindle mounted adapter and a balance head (either external or internal to the spindle).

Automatic Balancing enables the operator to ensure proper balancing with just the push of a button. The SBS automatic balancing solution is comprised of a computer control unit, a vibration sensor, and spindle-mounted adapter and a balance head (in either external or internal configurations). Once activated, sensors attached to the grinding machine detect and measure the imbalance and transmit this signal to the control unit, which automatically adjusts the position of counterweights inside the balance head to automatically and dynamically eliminate the vibration of the machine.

In order for the wheel of a grinding machine to accurately cut, produce smooth surface finishes, and generate correct part geometry, it is necessary to prevent vibration in the grinding process. A primary cause of vibration during grinding is the existence of imbalance in the grinding wheel. This is often due to the heterogeneous nature of the grinding wheel, which contains great numbers of unevenly distributed grains, causing intrinsic imbalance. This imbalance can be compounded by eccentric mounting of the wheel, varying width of the wheel, imbalance in the arbor, and coolant absorption into the wheel. Considering all these factors, even a carefully established initial balance will not last long. Furthermore, due to wear and dressing, the rotational dynamics of a grinding wheel are always changing. For these reasons, dynamic balancing of grinding wheels has long been recognized as an important step in the production process.